PREMIUM

BCD Series

OE Fit & Quality

Meets or exceeds OE specs

Chamfered

For less noise and even pad wear

Slotted

100% slotted for NVH* control

Ceramic formula

For an extended pad life

Ceramic Formulation

BCD Series

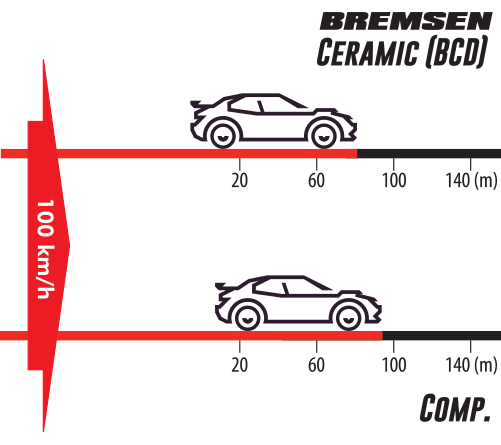

Braking distance efficency

BCD (Ceramic) vs. Others

Our ceramic brake pads as opposed to a semi metallic brake pad have less metal content. Metal is substituted with cooper (more heat tolerant) and ceramic fibre. The combination of cooper and ceramic fibre is the ultimate combination to not retaining heat. Our coated rotors and ceramic brake pads combined will maintain a safe braking distance.

Severe Duty

DMD Series

OE Fit & Quality

Meets or exceeds OE specs

Shimmed

Stainless-steel rubberized shims prevent noise and vibration

PowerShield

Help with the bedding process and insure a constant braking and grip

Chamfered

For less noise and even pad wear

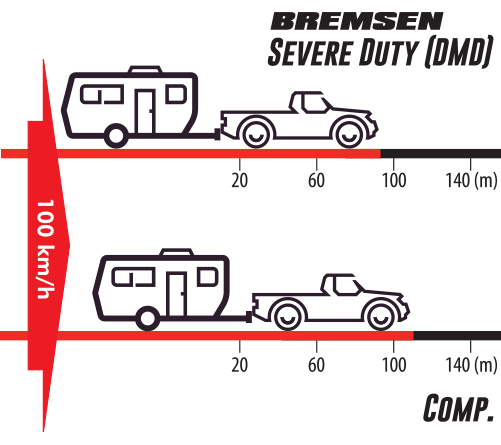

Braking distance efficency

DMD (Heay-Duty) vs. Others

The major effect on brake pads when a vehicle is loaded whether through towing or carrying weight is heat. When brakes are heated outside operating temperatures it leads to unfavourable braking and longer stopping distances. Loaded vehicles through towing and load carrying reach operating temperatures of the brakes at a faster rate and will rise above the parameters of operating temperatures.