100% NEW MATERIALS

GEOMET® COATED

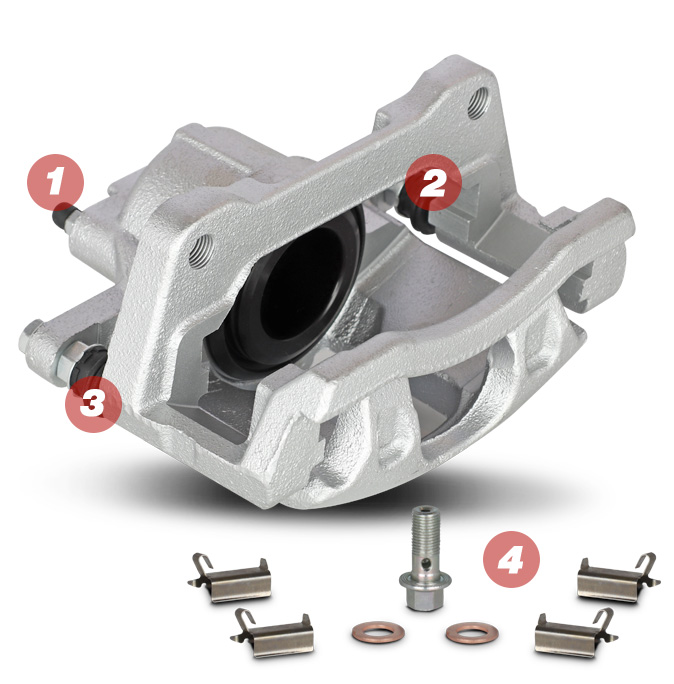

Bleeder Valve

Ensuring proper hydraulic pressure and optimal braking performance

Premium Grease

High quality grease on sliders to prevent premature jams

Double Ribbed

Double ribbed sealer slider bushings for longer life

Hardware Included

Banjo bolts and copper washers are included, where applicable

They are designed with high-quality materials and are treated with a water-based GEOMET® coating, specifically GEOMET® 360, to prevent rust and corrosion. Developed by the NOF Metal Coatings Group in response to stricter environmental standards, this coating is used worldwide on over 40 million brake components annually.

The Benefits of GEOMET® 360

Prevents rust, ultimately making your vehicle look better |

Unaltered braking performance |

High-temperature resistance |

Environmentally conscious |

It is not greasy, forms a very thin layer, and does not compromise braking performance. The coating can withstand temperatures up to 400°C (750°F), maintaining its protective qualities through heat cycles without crystallization or organic resin buildup. Additionally, GEOMET® coating is environmentally friendly—free of chromium and applied in a closed system that recycles leftover liquids, making it a sustainable choice for high-performance brake calipers.